Have you ever wondered what exactly constitutes a non-recurring engineering (NRE) fee when you receive an invoice from a precision machine shop?

There’s a misconception that NRE charges are additional fees, but rest assured—they aren’t. NRE charges are simply the costs associated with initial design, development, and manufacturing work on a part or product before it enters production.

What’s Involved in an NRE Charge?

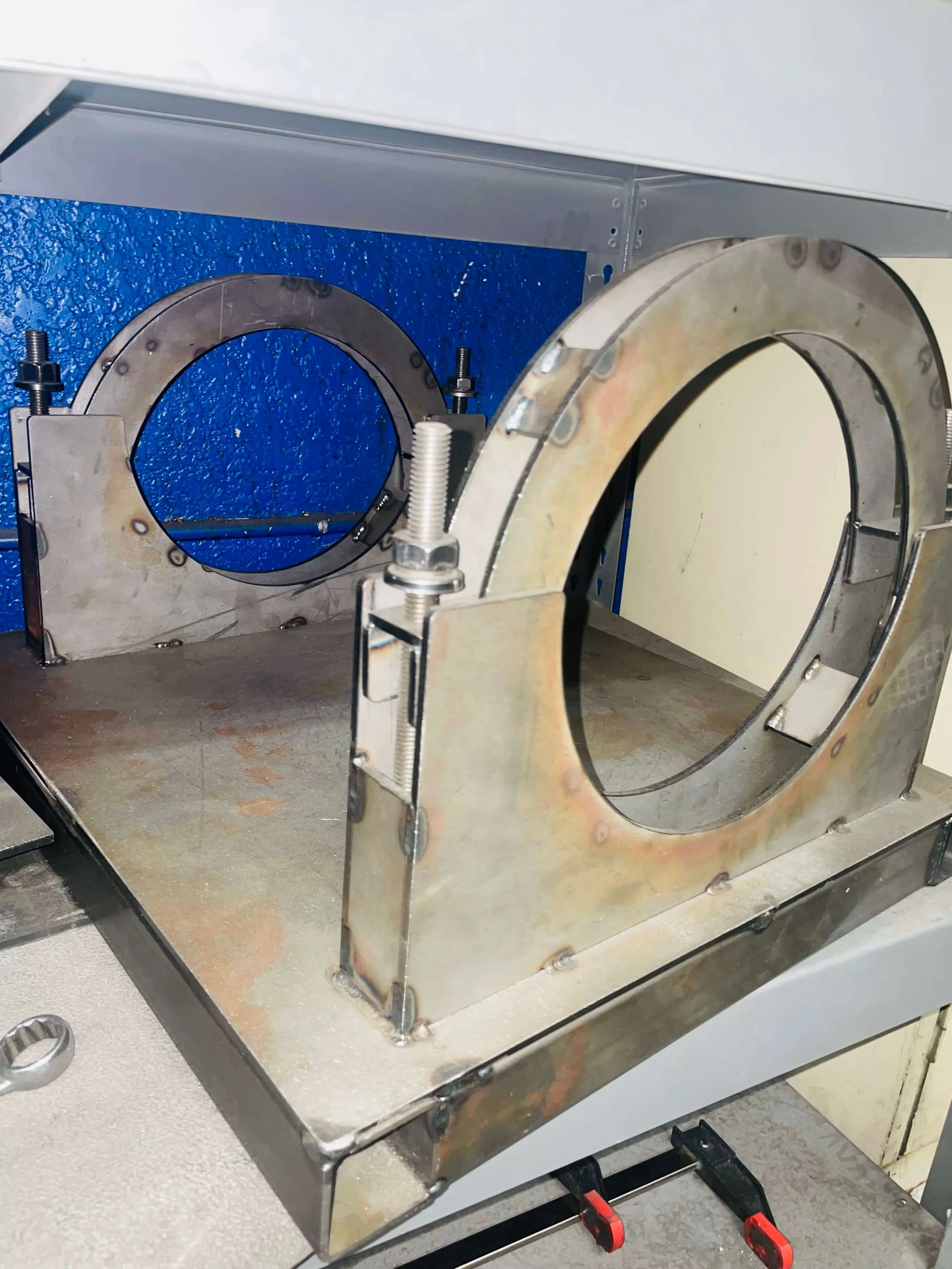

In addition to engineering time, NRE charges at Wal-Tek cover specific upfront work for jobs in both our precision machining and sheet metal fabrication divisions, such as the design and manufacturing of tooling and fixtures.

NRE charges also come into play when we’re tasked with reverse engineering a part. Sometimes customers come to us with a physical part they want to recreate and even mass produce, but they don’t have the accompanying prints. We pride ourselves on making parts to customer specifications, but if those specifications don’t exist, we must create them before we can build the parts.

We’re “the team you can trust” for the nuanced and technical job of working backward from a finished product. We can determine how to recreate it, producing new drawings and models to work from. However, like most precision machine shops, we do charge for this additional service. At our shop, that charge comes in the form of an NRE fee.

In many cases, NRE charges save customers time and money in the long run, which aligns with our commitment to always finding ways to better serve our customers. If a customer comes to us seeking thousands of parts, and we know we can run those parts more efficiently with a tool we’ll need to design and manufacture first, we’ll present that option and suggest an initial NRE charge.

Unlike Amortization, NRE Fees Can Lower the Cost per Part

Many full-service manufacturing companies, including Wal-Tek, prefer keeping NRE charges separate from production costs. By isolating the non-recurring engineering costs, we can lower the cost per part for our customers.

The “pre-work” necessary to run the job is completed upfront and billed separately, so the cost for all subsequent production runs reflects the actual price of the parts. By investing in our engineering services upfront, our customers can have a more solid margin to take to the market.

NRE fees also allow customers to take advantage of tax write-offs or other money-saving loopholes for research and development work. Some of our customers have had success getting reimbursed for itemized NRE charges.

The alternative to an NRE charge is amortization. Often, customers and manufacturers prefer to “bake in” the non-recurring engineering costs to the overall part cost. In these cases, the expense is spread out over time, as every part is made.

Wal-Tek Offers Two Types of NRE Charges

We offer two levels of NRE fees in both our precision machining division and sheet metal fabrication division:

1. A partner for production

Our first, most basic level begins with our upfront engineering work on your part. We then retain our intellectual property associated with the job. We own the drawings and the model and can run the job for you quickly and efficiently as needed.

Because we did the work to get the design and manufacturability right, you will save time and money by working with us for any future production runs. Whereas other shops would experience a learning curve during production, we already have all the necessary information and know what you need.

Our goal is to be your go-to partner for all your contract manufacturing needs—Wal-Tek can support you from prototype through production. An NRE charge is a great way to establish or solidify a partnership and ensure your precision machine shop has the necessary knowledge to make your parts as specified.

2. A standalone offering

Our second level includes the same upfront work from our trusted team of experts, but you—the customer—buy the rights to our intellectual property associated with the job.

In this higher service tier, customers purchase the completed drawings and models from us and then have the freedom to contract any manufacturing supplier to handle production.

Mini Case Study: 5 Reverse Engineered Parts

NRE charges can prove beneficial when our customers don’t have access to a robust design and engineering team and need to leverage our expertise to reverse engineer a part.

Recently, a new customer walked into our precision machine shop with five unique parts he and a friend were making. He didn’t have drawings or models—just parts. He was looking for a manufacturing partner now that his company was taking off.

We provided a non-recurring engineering cost analysis to outline the work involved to reverse engineer each of his parts, including creating a model and drawings. Each of the five individual parts took 8-12 hours to complete.

Now that the upfront work is done, we can quote the production costs for each part. Because the customer was looking for a partnership, we retained the rights to our intellectual property for his parts. We look forward to a mutually beneficial relationship for years to come.

Want to learn more about how an NRE charge can benefit you? Request a quote, and let’s discuss this option for your next project.